ANDRITZ DECANTER

- Double motor for energy recovery

- PLC control panel with touch screen

- Adjustable pipette

- Running with relative speed mode and torque mode

- Automatic greasing system

- Vibration sensor

- Bearing temperature sensor

- IIoT 4.0 as standard

- METRIS addIQ control system

- Pipette design able to adjust pick-up of the light phase

- Wear protection to ensure longer life cycle

- Two motor regenerative drives to adjust the differential speed even during operation, optimizing the phase separation and consequently, oil yield

- Possibility of reducing speed contributes to minimizing vibration as well as wear and tear

- Two frequency converters for speed control in energy regenerating mode

- ANDRITZ TurboWISE feed chamber design helps to ensure gentle feed and less shear force acting on the product, with no emulsion formation

- Deep pond depth allows optimum capacity and retention time, and lower energy consumption

- Unique scroll design for lowest oil loss in the cake and separation of the liquid phases

- Easy maintenance of the bowl and scroll, i.e. balancing is possible on site

- Fully replaceable wear parts, even the tile for scroll protection, for a fast and easy regenerative procedure with substantial cost savings

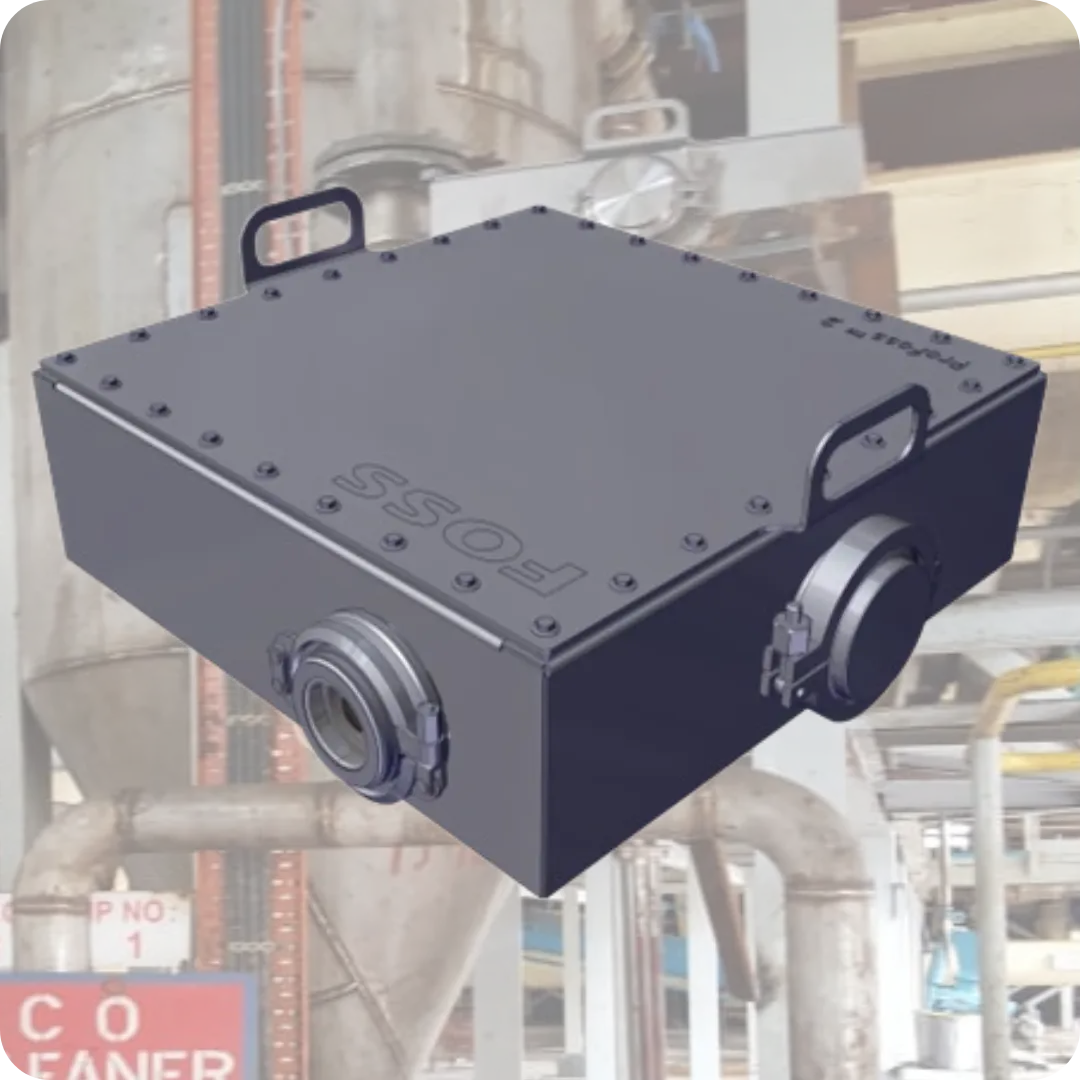

- FOSS NIR integrated